BHS-Sonthofen GmbH

Booth number: B 120/2

www.bhs-sonthofen.com

About us

BHS-Sonthofen is an owner-operated group of companies specializing in machinery and plant engineering with headquarters in Sonthofen, Germany.

In keeping with our mission "Transforming Materials into Value," we offer innovative process solutions, technologies and consulting services in the business areas Process Technology, Building Materials Machinery, as well as Recycling & Environment.

Our experts in the field of mechanical and thermal process technology with a focus on filtration, drying, mixing, crushing, and recycling form the basis for our success.

Our company has a global presence, with 500 employees, four production facilities and nine subsidiaries

Address

An der Eisenschmelze 47

87527 Sonthofen

Germany

E-mail: info@bhs-sonthofen.com

Phone: +49 8321 6099-0

Internet: www.bhs-sonthofen.com

Contact person:

Muslim Magomaev

Managing Director

E-mail: muslim.magomaev@bhs-sonthofen.com

Phone: +7 915 374-1304

Products & Services

MIXING TECHNOLOGY:

• Twin-shaft batch mixer (DKX)

• Dry powder batch mixer (DMX)

• Twin-shaft continuous mixer (LFK)

• Single-shaft continuous mixer (MFKG)

• Planetary mixer (BPX)

• Laboratory mixer

• Retrofitting concrete mixing plants

CRUSHING TECHNOLOGY:

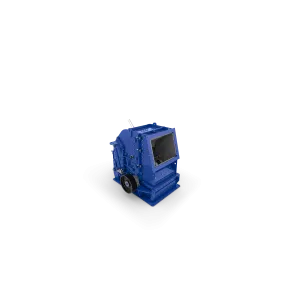

• Impact crusher (PB)

• Impact mill (PM)

• Rotor impact mill (RPM)

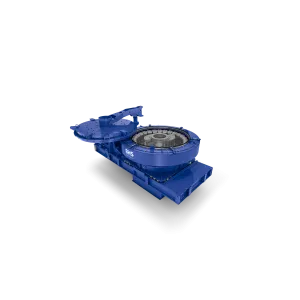

• VSI Rotor centrifugal crusher (RSMX)

• Stationary aggregates plants

Twin-Shaft Batch Mixer (DKX)

Twin-shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing technique has a significant effect on the uality of the mixture and the economic efficiency of the production process.

VSI Rotor Centrifugal Crusher (RSMX)

The BHS rotor centrifugal crusher RSMX is used for crushing and shaping all types of minerals – soft or hard, moderately or extremely abrasive.

Impact crushers & impact mills (PB & PM)

BHS Impact Crushers and Impact Mills are a universal and economical solution. The BHS Impact Crusher achieves very high crushing ratios in both the first and second stage. This already results in a broad range of saleable cubical final products. To manufacture fine grains, the Impact Crusher can be converted to the higher specification Impact Mill, with this flexible solution, you benefit from excellent crushing results and can respond at any time to changing project requirements.

Planetary mixer (BPX)

The mixing technology is suitable for all fine-grained formulations and offers comprehensive benefits for this purpose. The mixing procedure has a significant effect on the quality of the mixture produced and the economic efficiency of the production process.